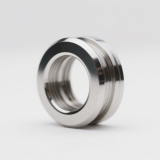

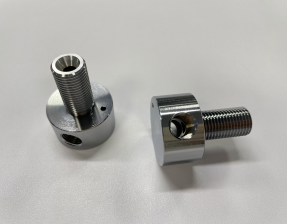

Plating is a type of coating in which a metal is deposited on a conductive surface. corrosion-resistant properties, enhanced solderability, hardness, and reduced friction, including Nickel Plating, Silver Plating, Gold Plating, Chrome Plating, Zinc Plating, and Tin Plating.

Plating is a surface finishing process where a thin layer of metal (such as nickel, chrome, or gold) is deposited onto the surface of a workpiece using an electric current.

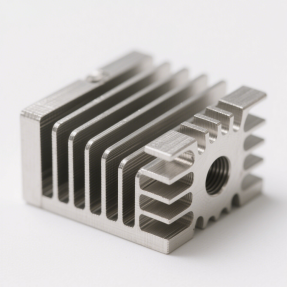

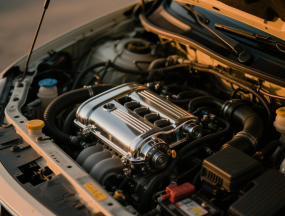

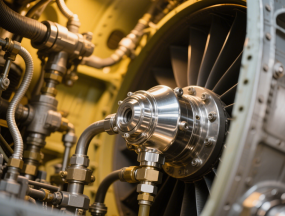

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

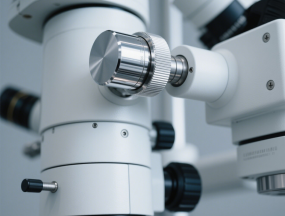

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| 01 | Degreasing Removes surface oil, grease, and contaminants to ensure clean adhesion. Typical Parameters: Alkaline cleaner, 50–70 °C, 2–5 min. Standards: ISO 9001:2015 Quality Management System; | Standards: ISO 9001:2015 Quality Management System; | |

| 02 | Rinsing Flushes away chemical residues to avoid contamination in the next step. Typical Parameters: Tap or deionized water rinse, RT, 1–2 min. Standards: In-house PL-SOP12-02; | Standards: In-house PL-SOP12-02; | |

| 03 | Acid Pickling / Activation Flushes away chemical residues to avoid contamination in the next step. Typical Parameters: HCl or H₂SO₄, 10–25% conc., 1–3 min. Standards: ASTM A380 Metal Surface Cleaning; | Standards: ASTM A380 Metal Surface Cleaning; | |

| 04 | Rinsing Ensures the surface is neutral and clean before plating begins. Typical Parameters: DI water rinse, RT, 1–2 min. Standards: In-house PL-SOP12-04; | Standards: In-house PL-SOP12-04; | |

| 05 | Strike Plating (e.g., Copper) Applies a thin base layer to improve bonding with the main coating. Typical Parameters: Current density 1.5–3 A/dm², 10–30 s. Standards: ISO 4526 Adhesion Test for Plating Layers; | Standards: ISO 4526 Adhesion Test for Plating Layers; | |

| 06 | Main Plating (Ni, Cr, Au, etc.) Deposits the desired metal coating (e.g., nickel, chrome, gold) for appearance and function. Typical Parameters: Ni: 2–4 A/dm², 5–25 μm; Cr: 5–12 V, 0.2–2 μm; Au: 0.1–0.3 A/dm², 0.5–2 μm. Standards: Ni: ISO 4527; Cr: ISO 1456; Au: MIL‑C‑5541; | Standards: Ni: ISO 4527; Cr: ISO 1456; Au: MIL‑C‑5541; | |

| 07 | Rinsing Removes remaining plating solution and prevents staining or corrosion. Typical Parameters: DI water rinse, RT, 1–2 min. Standards: In-house PL-SOP12-07; | Standards: In-house PL-SOP12-07; | |

| 08 | Passivation / Sealing Adds protective treatment to enhance corrosion resistance and finish. Typical Parameters: Chromate or organic sealer, RT, 2–5 min. Standards: ASTM B607 Sealing Test for Plating Layers; | Standards: ASTM B607 Sealing Test for Plating Layers; | |

| 09 | Drying Dries the workpiece thoroughly to avoid water spots or corrosion. Typical Parameters: Hot‑air or vacuum dry, 60–100 °C, 10–30 min. Standards: In-house PL-SOP12-09; | Standards: In-house PL-SOP12-09; | |

| 10 | Final Inspection Verifies coating thickness, adhesion, and surface quality before delivery. Typical Parameters: Thickness: 1–25 μm (ISO 2177); Adhesion ≥5 MPa (ASTM B571); Salt spray ≥96 h (ASTM B117). Standards: ISO 2177; ASTM B571; ASTM B117; | Standards: ISO 2177; ASTM B571; ASTM B117; |

| Property | Typical Range |

| Coating Thickness | 1–50 μm (varies by type) |

| Adhesion Strength | ≥ 5 MPa (ASTM B571) |

| Surface Hardness | Up to 1000 HV |

| Conductivity | Excellent for gold, silver, copper plating |

| Thermal Resistance | Up to 300°C |

Tell us your part material, function, and appearance requirements, and we'll recommend the best plating solution for your needs.