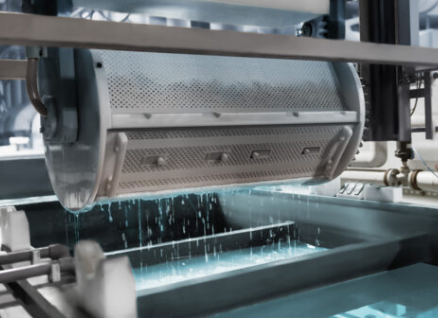

Common problems of surface treatment

We have prepared a "Common Problem Analysis Report" to clearly explain the causes of various abnormalities and the corresponding standard solutions to ensure that the processing process is transparent and traceable.

For appearance products, 100% full inspection regardless of the order volume or quality requirements to prevent defective products from flowing out.

If it is found that the product does not meet the standard:

1) Immediately start a special communication process and explain the details of the problem in writing.

2) Simultaneously submit a rework/replacement plan for your confirmation.

3) Perform subsequent operations after authorization, and there will be no uninformed shipment behavior.

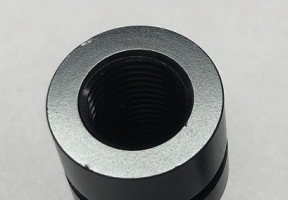

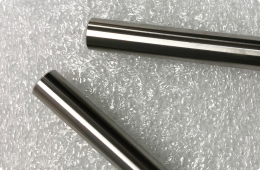

As Machined

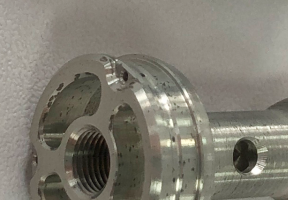

As Machined  Bead Blast

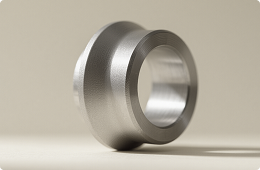

Bead Blast  Polishing

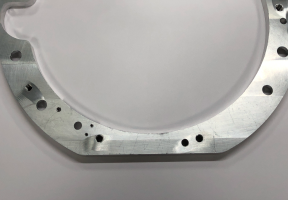

Polishing  Anodizing

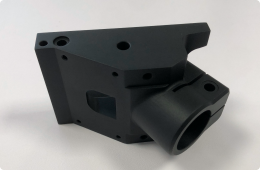

Anodizing  E-Coating

E-Coating  Heat Treatment

Heat Treatment  Brushed Finish

Brushed Finish  Powder Coating

Powder Coating  Plating

Plating  Painting

Painting  Passivation

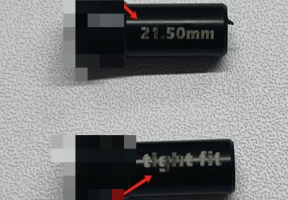

Passivation  Laser Engraving/CNC engraving

Laser Engraving/CNC engraving