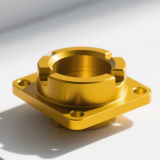

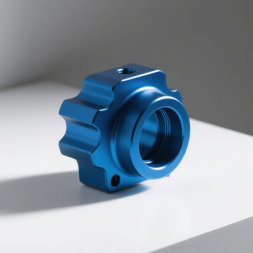

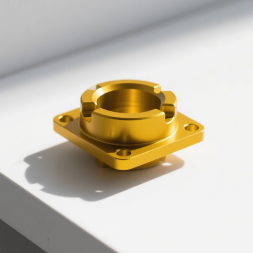

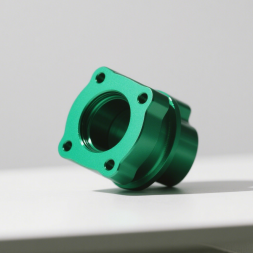

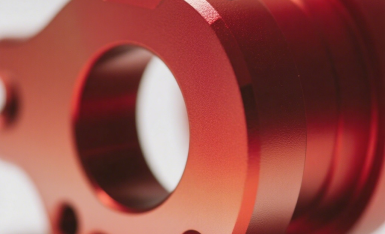

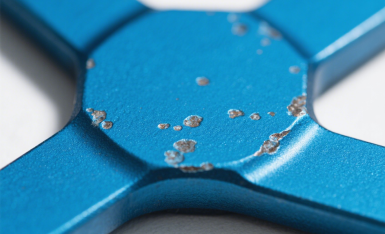

Anodizing improves corrosion resistance and wear properties, and enables color dyeing, making it perfect for aluminum parts.

Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum parts. This layer increases resistance to wear and corrosion and can be dyed in various colors for enhanced aesthetics.

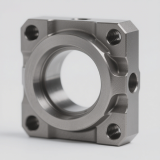

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

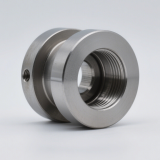

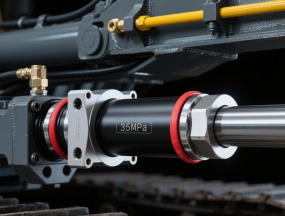

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

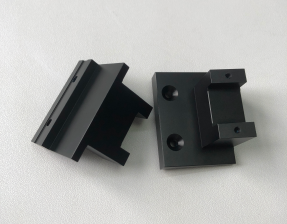

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| 01 | Degreasing Remove oils and organic residues. Typical Parameters: Alkaline solution, 50–70°C, 3–5 min. Standards: In-house AD-SOP12-01 | Standards: In-house AD-SOP12-01 | |

| 02 | Etching Uniform surface for oxidation. Typical Parameters: NaOH 5–10%, 40–60°C, 3–5 min. Standards: In-house AD-SOP12-02; | Standards: In-house AD-SOP12-02; | |

| 03 | Desmut Remove residues from etching. Typical Parameters: HNO3 or H2SO4, 20–30°C, 1–3 min. Standards: In-house AD-SOP12-03; | Standards: In-house AD-SOP12-03; | |

| 04 | Anodizing Electrolytic oxidation in sulfuric acid bath. Typical Parameters: Type II: 18–22V, 20°C, 30–45 min Type III: 24–30V, 0–5°C, 60 min Standards: MIL-A-8625FISO 7599GJB 150; | Standards: MIL-A-8625FISO 7599GJB 150; | |

| 05 | Color Dyeing (Optional) Decorative or functional coloring. Typical Parameters: Depends on dye type. Standards: In-house AD-SOP12-05; | Standards: In-house AD-SOP12-05; | |

| 06 | Sealing Enhance corrosion resistance. Typical Parameters: Boiling DI water or nickel acetate, 95–100°C, 15–30 min. Standards: ISO 7599 recommended; | Standards: ISO 7599 recommended; | |

| 07 | Drying & Inspection Quality inspection before packaging. Typical Parameters: Hot air drying, room temp QC. Standards: In-house AD-SOP12-07; | Standards: In-house AD-SOP12-07; |

| Property | Typical Range |

| Coating Thickness | 5–25 μm (Type II), up to 50 μm (Type III) |

| Surface Roughness | Ra 0.8–3.2 μm depending on pre-treatment |

| Hardness | Up to 500 HV (Type III) |

| Dielectric Strength | ~1000 V per 25 μm |

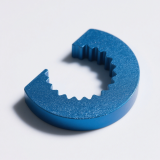

| Available Colors | Clear, Black, Red, Blue, Gold, Green, Custom |

| Base Materials | Aluminum and aluminum alloys only |

Tell us your part material, function, and appearance requirements, and we'll recommend the best anodizing solution for your needs.