Why We Conduct Order Review

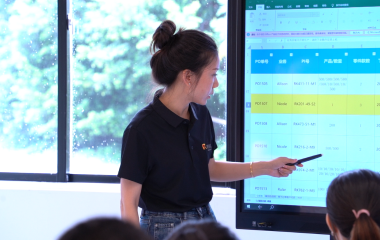

At REKO, every order must go through a mandatory and rigorous review before production begins. This process ensures that every project is delivered on time, on spec, and with full transparency.

At REKO, every order must go through a mandatory and rigorous review before production begins. This process ensures that every project is delivered on time, on spec, and with full transparency.

Order review is conducted twice a week — Monday and Wednesday.

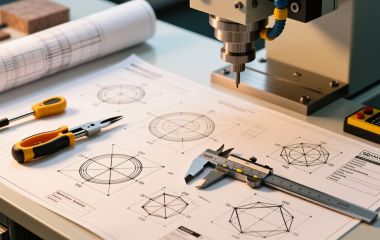

Can the part be manufactured exactly according to the customer's drawings?

Are there tolerance conflicts, material limitations, or process challenges?

Do our machines, manpower, and processing capabilities meet the required timeline and quality?

Based on capacity and workflow evaluation, we provide a delivery time that is accurate and achievable.

We evaluate each risk and define preventive actions.

We confirm all expectations such as:

This multi-perspective evaluation ensures a complete and reliable assessment of every order.

We verify the entire production flow:

Material → Machining → Surface treatment → Inspection → Packaging → Shipping

Every step must be feasible and controlled.

We evaluate whether the delivery schedule is achievable based on:

For aerospace, medical, automotive, and mission-critical industries, we perform additional checks:

Issues are identified in advance, reducing rework and waste.

A smoother workflow minimizes delays.

Risks are eliminated before machining starts.

Reliable planning gives customers confidence and consistency.

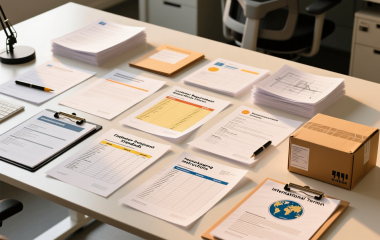

Ensuring Accuracy, Traceability & Minimal Disruption When Customers Update Drawings In real production, drawing revisions are common — especially for aerospace, medical, automotive and R&D projects.

At REKO, we have a strict and traceable Drawing Change Management System to ensure every update is handled smoothly and without risk.

Only after full verification do we proceed to the next step.

Any risks or delays will be clearly communicated to the customer.

This ensures transparency and prevents misunderstandings.

This is especially important for aerospace/medical compliance.

This prevents errors after the drawing change.

Nothing is done until the customer approves.

We aim to minimize delays and cost impact while ensuring full compliance to the latest design.