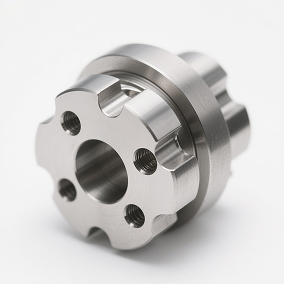

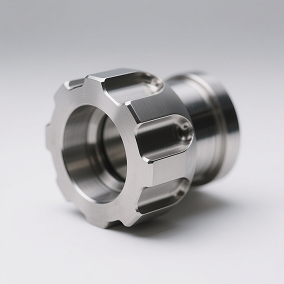

Durable. Precise. Corrosion-resistant. Our stainless steel CNC machining delivers high-strength components built for critical applications.

Tolerance down to 0.0005 inches(0.01mm)

No minimum order quantity

Over 40 Certified Materials

Delivery in as little as 5 days

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Alloy | Temp Resistance (°C) | Hardness (HB) | Cost | Common Applications | Surface Treatment Limitations | Key Features |

| SUS201 | 760℃ | 210 | $$ | Household hardware, kitchen utensils | Not suitable for high-polish finish | Economical, moderate corrosion resistance |

| SUS303 | 760℃ | 190 | $$$ | Precision parts, gears, screws | Limited corrosion resistance post-machining | Excellent machinability |

| SUS304/304L | 870℃ | 160 | $$$ | Food processing equipment, piping | Suitable for most finishes, except high-chloride anodizing | Good corrosion resistance, widely used |

| SUS316/316L | 925℃ | 150 | $$$$ | Marine components, medical devices | May require passivation for medical use | Superior corrosion resistance, especially in chlorides |

| SUS416 | 870℃ | 240 | $$$ | Valve parts, gears, shafts | May discolor during heat treatment | Free-machining, strong and hardenable |

| SUS420 | 650℃ | 250 | $$$ | Knife blades, surgical instruments | Requires careful control during hardening | Wear-resistant, suitable for cutting tools |

| SUS430 | 815℃ | 180 | $$ | Decorative trim, appliances | Limited to basic polishing and passivation | Ferritic, magnetic, cost-effective |

Polishing For high-gloss and mirror-like finish. Commonly used in decorative or sanitary applications. | Not protective, may show scratches easily. | SUS304, SUS316, SUS303 |

Bead Blasting Produces a smooth, matte, or satin finish. Removes surface contaminants. | Slight material erosion, not protective alone | All stainless grades |

Passivation Removes free iron and enhances corrosion resistance by forming a passive oxide layer. | Does not change appearance, not suitable for all alloys | SUS304, SUS316 |

Electropolishing Electrochemical process that smooths the surface and enhances corrosion resistance. | May not be suitable for parts with tight tolerances | SUS304, SUS316 |

Black Oxide (on Stainless Steel) Provides a uniform black finish with mild corrosion resistance. | Mostly aesthetic, not highly durable | SUS430, SUS420, SUS416 |

REKO provides high-precision CNC machining for stainless steel parts, from prototypes to mass production. We serve global industries including medical, aerospace, automotive, and energy — delivering durable, corrosion-resistant components with fast turnaround and reliable quality.