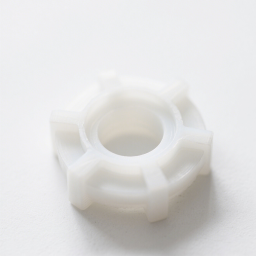

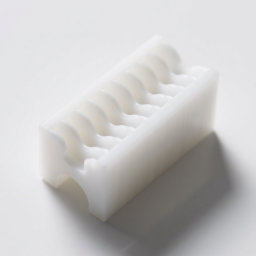

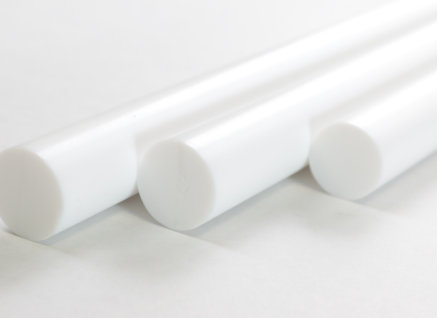

At REKO, we offer high-precision CNC machining of PTFE ptferts, ensuring tight tolerances and consistent quality for your custom plastic components.

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Property | Typical Value | Unit | Notes |

| Density | ~2.15–2.18 | g/cm³ | Indicates material mass per volume; useful for weight-sensitive designs. |

| Tensile Strength | 13–25 MPa (~1,900–3,600 psi) | MPa / psi | Measures resistance to pulling forces; reflects structural strength. |

| Elongation at Break | 200–400 | % | High ductility; stretches significantly before breaking. |

| Tensile Modulus | ~600 MPa (~87 ksi) | MPa / ksi | Reflects stiffness; low modulus means more flexibility. |

| Hardness (Shore D) | ~50–60 | Shore D | Measures surface hardness; affects wear and scratch resistance. |

| Compressive Strength (1% deformation) | ~4–5 | MPa | Ability to resist compression before permanent deformation. |

| Heat Deflection Temperature (264 psi) | ~55 °C (132 °F) | °C / °F | Temp at which material deforms under a load; important for thermal performance. |

| Melting Temperature | ~327 °C (621 °F) | °C / °F | Indicates transition to molten state; upper limit for processing. |

| Maximum Operating Temperature | Up to ~260 °C (500 °F) | °C / °F | Maximum long-term use temperature without degradation. |

| Coefficient of Thermal Expansion | ~1.2–1.7 × 10⁻⁴ K⁻¹ | µm/m·°C | Indicates expansion rate under heat; critical for dimensional control. |

| Thermal Conductivity | ~0.25 | W/m·K | Low value indicates good thermal insulation. |

| Coefficient of Friction (against steel) | ~0.05–0.10 | -- | Extremely low; enables smooth motion and reduces wear in sliding parts. |

| Dielectric Constant (1 MHz) | ~2.1 | -- | Excellent insulator; ideal for high-frequency electronic applications. |

| Volume Resistivity / Surface Resistivity | >10¹⁸ | Ω·cm | Extremely high electrical resistance; prevents leakage currents. |

| Water Absorption (24 h) | < 0.01 | % | Very low moisture uptake; stable in humid environments. |

As Machined When machined, PTFE typically exhibits a natural matte finish ranging from approximately Ra 3.2 to 6.4 µm. This finish features subtle tool marks and retains PTFE's characteristic low-friction surface. | Sealing components, insulators, guides |

Bead Blast Masks tool marks and improves visual consistency or grip without sacrificing performance. | Visual parts, grips, ergonomic surfaces |

Polishing PTFE polishing methods vary by need,mechanical polishing suits simple shapes with low smoothness requirements, chemical polishing fits complex parts, and plasma polishing offers high-quality results but at higher cost. | Valves, medical parts, food-contact parts |

Due to PTFE's low surface energy and thermal limits, surface preparation (e.g., plasma activation, drying) is often necessary before coating or bonding.

Polytetrafluoroethylene (PTFE) is valued for its extreme chemical resistance, low friction, and thermal stability. Its unique physical behavior requires specialized machining parameters to achieve reliable results.

| Parameter | Recommended Range | Notes |

| Tooling | Razor-sharp carbide or HSS tools, high positive rake (15–30°), side relief 10–20°, large nose radius | Rounded cutting edges shear cleanly—avoids thermal flattening or burrs |

| Cutting Speed (SFM) | 250–800 SFM (≈75–240 m/min); 200–500 SFM preferred for fine finish | High speed promotes shearing vs. smearing; avoid exceeding 500 °C to prevent toxic fumes |

| Feed Rate (IPR) | 0.001–0.005″/rev (≈0.03–0.13 mm/rev) | Low feed reduces cutting force and heat buildup |

| Depth of Cut (DOC) | Shallow cuts, e.g., ≤0.25″ (~6 mm) per pass | Minimizes thermal distortion and creep (cavitymold.com, Hopeful) |

| Cooling Strategy | Usually dry; compressed air cooling for chip clearing; light mist only if needed | PTFE's low thermal conductivity makes coolant less effective; avoid moisture-induced swelling (Hopeful, Hopeful) |

| Workholding & Fixturing | Custom fixtures or support to prevent deflection; soft jaws or low pressure for clamping | PTFE is soft and prone to shifting/distortion under pressure |

| Annealing (Stress Relief) | Pre-machining anneal below melting point (per part thickness); re-annealing between rough and finish cuts | Releases internal stresses, enhancing dimensional stability and reducing post-machining creep (vitalpolymers.com, cavitymold.com) |

| Tolerance & Stability | Standard tolerance ±0.001–0.002″ (0.025–0.05 mm); tighter requires annealing and controlled workholding | High thermal expansion (~1–1.3%) and creep make ultra-precision challenging (machining-custom.com, cavitymold.com) |

Our CNC‑machined PTFE (Teflon) components serve industries such as aerospace, medical devices, chemical processing, electronics, and food handling. Thanks to PTFE's ultra‑low friction, exceptional chemical inertness, electrical insulation, and temperature stability (–200 °C to +260 °C), it's the go‑to material for seals, bushings, valve seats, insulators, and wear rings where cleanliness and reliability matter.