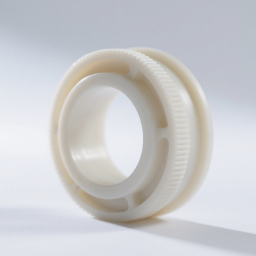

At REKO, we offer high-precision CNC machining of POM parts, ensuring tight tolerances and consistent quality for your custom plastic components.

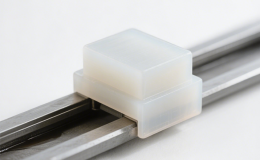

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

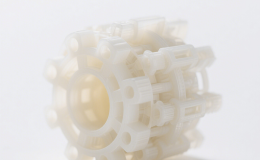

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Property | Typical Value | Unit | Notes |

| Density | 1.41 | g/cm³ | High structural density suitable for precision parts |

| Tensile Strength | 60–70 | MPa | Strong tensile performance under stress |

| Elongation at Break | 30–50 | % | Good ductility, less prone to cracking |

| Flexural Strength | 90–110 | MPa | High resistance to bending, ideal for structural components |

| Flexural Modulus | 2500–3100 | g/cm³ | Excellent rigidity and shape retention |

| Impact Strength (Unnotched) | 6–10 | kJ/m² | Moderate impact resistance for general use |

| Hardness (Rockwell) | R95–R120 | -- | High surface hardness with good scratch resistance |

| Melting Point | 165–175 | °C | Requires precise temperature control during processing |

| Continuous Use Temperature | 100–120 | °C | Performs well under prolonged elevated temperatures |

| Short-term Max Temperature | 140–160 | °C | Maintains integrity under short-term heat exposure |

| Coefficient of Friction | 0.2 | -- | Low friction, ideal for sliding components |

| Water Absorption | 0.2–0.8 | % | Low moisture absorption ensures dimensional stability |

| Dielectric Strength | 19 | kV/mm | Excellent electrical insulation properties |

| Volume Resistivity | >10¹³ | Ω·cm | Strong resistance to electrical conduction |

| Thermal Expansion Coefficient | 110 | µm/m·°C | Stable expansion under thermal variations |

| Chemical Resistance | Good | -- | Resistant to acids, bases, alcohols, and ketones |

| Machinability | Excellent | -- | Smooth cutting and high CNC accuracy |

| FDA Compliance | Available | -- | Certain grades approved for food & medical use |

Polishing Improve surface finish and enhance part appearance | Gears, sliding components, visible housings |

Painting Enhance aesthetics, suitable for multi-color housing parts | Consumer electronics, industrial enclosures |

POM is not suitable for metal surface treatments such as anodizing and electroplating.

We machine every material with precision, strictly following its unique properties to ensure the best performance and surface quality. Our team continuously explores and refines the CNC machining strategies for each material, optimizing cutting parameters to achieve greater consistency, accuracy, and efficiency.

| Parameter | Recommended Range | Notes |

| Cutting Tool | Carbide tools preferred | Offers better wear resistance and surface finish |

| Spindle Speed | 6,000 – 12,000 RPM | Moderate speed avoids melting due to low thermal conductivity |

| Feed Rate | 500 – 1,500 mm/min | Adjust based on wall thickness and part complexity |

| Depth of Cut | 0.5 – 2 mm | Shallower passes reduce deformation and maintain accuracy |

| Coolant | Air blast or dry cutting | Coolant often not necessary; use air to remove chips |

| Clamping | Use soft jaws or padding | Avoid deformation due to clamping pressure |

| Toolpath Strategy | High-speed machining | Reduces heat buildup and improves surface quality |

| Finishing Pass | Optional (0.2–0.5 mm) | Improves tolerance and surface smoothness |

| Chip Removal | Required | Prevents chip re-cutting and surface scratches |

POM is easy to machine but may warp if excessive heat builds up.

Ensure sharp tools and avoid tool dwell to maintain dimensional accuracy.

Avoid excessive polishing which could deform thin-wall parts.

REKO offers high-precision CNC machining services for POM (Acetal) components, from rapid prototyping to full-scale production. Our POM parts are widely used in industries such as automotive, electronics, industrial automation, consumer products, and medical equipment — delivering excellent wear resistance, low friction, dimensional stability, and mechanical strength for high-performance plastic applications.