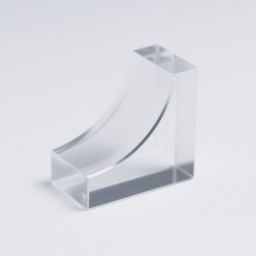

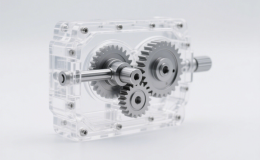

Get precise, clear acrylic parts through our CNC machining service. We provide smooth finishes, intricate designs, and consistent quality for both aesthetic and functional uses. Request a fast quote online and get custom acrylic parts made to your exact specs.

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Property | Typical Value | Unit | Notes |

| Density | 1.18–1.20 | g/cm³ | Lightweight material for structural and optical use |

| Tensile Strength | 60–75 | MPa | Good strength under tension |

| Elongation at Break | 2–6 | % | Low ductility; not ideal for high flexibility |

| Flexural Strength | 90–120 | MPa | Resists bending, suitable for rigid parts |

| Flexural Modulus | 2800–3200 | MPa | Indicates high stiffness |

| Izod Impact Strength (Notched) | 1.5–3.5 | kJ/m² | Brittle compared to other plastics |

| Hardness (Rockwell) | M95–M100 | -- | Moderate surface hardness |

| Light Transmittance | ~92 | % | Excellent optical clarity, similar to glass |

| Refractive Index | 1.49 | -- | Defines how much light is bent in the material |

| Vicat Softening Point | 100–110 | °C | Begins to soften under heat at this range |

| Heat Deflection Temp (HDT) | 90–100 | °C (at 1.8 MPa) | Max temp under load before deformation |

| Coefficient of Thermal Expansion | ~70–77 ×10⁻⁶ | 1/°C | Moderate expansion with temperature changes |

| Surface Resistivity | 10¹³–10¹⁵ | Ω·cm | High resistance to electrical conduction |

| Water Absorption (24h) | 0.3 | % | Low moisture uptake, good dimensional stability |

| Flammability Rating | HB | UL 94 | Basic flame resistance; not self-extinguishing |

As Machined Transparent or translucent finish depending on the toolpath and cutting speed. | Prototype enclosures, functional test parts. |

Sand Blasting Creates a frosted or matte surface, reduces tool marks. | Lighting covers, decorative panels. |

Painting Adds color or branding using spraying or rolling techniques. | Consumer electronics, product housings. |

Polishing Mechanical buffing for a smooth, high-gloss transparent finish. | Display windows, luxury components. |

Flame Polishing Flame-heated surface reflow for a glass-like clarity. | Transparent edges, light guides. |

UV Curing UV light forms a scratch-resistant protective coating. | Outdoor-use parts, optical surfaces. |

PMMA cannot be anodized or electroplated. It is best suited for optical and decorative surface enhancements.

We offer CNC machining services for PMMA (Acrylic), a transparent thermoplastic known for its clarity and rigidity. Below are general machining recommendations to achieve optimal results. Actual settings may vary depending on part geometry and machine setup.

| Parameter | Recommended Range | Notes |

| Cutting Style | Conventional milling | Minimizes surface melting and improves edge clarity |

| Spindle Speed | 18,000 to 24,000 RPM | Since higher cutting speeds for pmma are needed to avoid melting the material and yield cleaner cuts. |

| Feed Rate | 500 – 1,000 mm/min | Moderate feed rate helps prevent chipping and cracking |

| Depth per Pass | 0.25 – 0.5 mm | Shallow cuts reduce stress and improve dimensional accuracy |

| Coolant | Air blast or mist cooling | Avoid flood coolant to prevent stress cracking |

| Fixturing | Use soft jaws or vacuum holding | Prevents scratching or deformation during machining |

| Threading / Tapping | Use inserts or adhesives | Direct threading not recommended; use brass inserts for strength |

| Polishing | Flame / vapor / buff polishing | Restores transparency and achieves optical-grade finish |

Our PMMA (Acrylic) CNC‑machined components serve industries such as lighting & optics, medical & lab equipment, consumer electronics, architecture, and automotive interiors. With approximately 92% light transmission, excellent UV stability, tight tolerances, and flexible surface finishing, our parts are engineered for both aesthetic and technical performance, including light guides, lenses, instrument covers, and decorative panels.