Get high-performance PEEK parts precisely machined to your specs. REKO delivers tight tolerances, reliable quality, and excellent mechanical and thermal properties — ideal for demanding applications.

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Property | Typical Value | Unit | Notes |

| Density | 1.30 – 1.32 | g/cm³ | Material weight per volume |

| Tensile Strength (Yield) | 90 – 110 | MPa | Strength before permanent stretch |

| Tensile Modulus | ~4,000 | MPa | Stiffness under tension |

| Elongation at Break | 20 – 50 | % | Flexibility before breaking |

| Flexural Strength | 160 – 172 | MPa | Resistance to bending |

| Flexural Modulus | ~3,800 – 4,300 | MPa | Bending stiffness |

| Compressive Strength | ~125 | MPa | Resistance to compression |

| Hardness (Shore D) | ~85 – 90 | -- | Surface hardness rating |

| Notched Impact (Charpy) | ~7 kJ/m² | kJ/m² | Impact toughness |

| Water Absorption (24 h) | ~0.1 %, Saturation ~0.5 % | % | Moisture uptake over time |

| Glass Transition Temp (Tg) | ~143 | °C | Softening point before melting |

| Melting Point (Tm) | ~340 – 343 | °C | Temperature at melting |

| Heat Deflection Temp (HDT, 1.8 MPa) | ~160 | °C | Temp where shape starts to deform under load |

| Max Continuous Service Temp | ~240 – 260 | °C | Max long-term use temperature |

| Coefficient of Thermal Expansion | ~45 µm/m·°C (<Tg) / ~120 µm/m·°C (>Tg) | ppm/°C | Expansion below/above Tg |

| Thermal Conductivity | ~0.25 – 0.29 | W/m·K | Heat transfer ability |

| Electrical Resistivity | ~10¹⁶ Ω·cm | Ω·cm | Electrical insulation strength |

As Machined Natural finish after machining, minimal processing | Functional parts, internal components |

Sand Blasting Creates a matte/frosted look, hides tool marks | Aesthetic parts, display housings |

Teflon Coating Enhances wear resistance, reduces friction | Gears, sliding parts, wear surfaces |

Painting Custom spray colors, adds protection | Enclosures, consumer-facing components |

Powder Coating Durable and colorful finish for harsh environments | Industrial covers, customized housings |

PEEK has excellent inherent properties and typically does not require plating or anodizing. However, certain coatings (like Teflon or paint) can further enhance performance or appearance.

We offer CNC machining services for PEEK (Polyether Ether Ketone), a high-performance engineering thermoplastic. Below are recommended guidelines to achieve precision components. Actual settings may vary with machine tools, coatings, and part geometry.

| Parameter | Recommended Range | Notes |

| Tooling | Solid carbide for unfilled; diamond‑coated/PCD for CF/GF grades | Sharp tools, positive rake (≈10–15°), polished flutes improve chip flow and surface finish |

| Cutting Speed (SFM) | Unfilled: 300–500 SFM CF/GF: 200–450 SFM | Adjust speed by grade to manage heat and tool life |

| Feed per Tooth / Rev | 0.005–0.020″ (≤ 0.15 mm/rev) | Reduce feed for filled grades to ~75–85% of unfilled rate |

| Depth of Cut (DOC) | Rough: ≤ 0.020″ (~0.5 mm) Finish: ≤ 0.015″ (~0.4 mm) | Prefer multiple shallow passes over deep cuts |

| Coolant Strategy | Unfilled: compressed air CF/GF: mist or water‑soluble coolant | Air preferred for medical-grade machining; coolant prevents heat stress |

| Machining Strategy | Climb milling, ramped entry, intermittent cuts | Reduces friction, prevents hot spots and dimensional drift |

| Annealing (Stress Relief) | Pre‑machining: 2–4 hrs at 150–200 °C Post‑roughing: optional additional anneal | Enhances dimensional accuracy and reduces cracking |

| Fixturing | Use vacuum tables, soft jaws, or internal plugs | Avoid distortion on thin-walled or long parts; reduce torque-induced shift |

| Tolerances / Surface Finish | Down to ±0.02 mm; surface finish Ra ~1.6 µm achievable | Maintain sharp tools, controlled thermal environment |

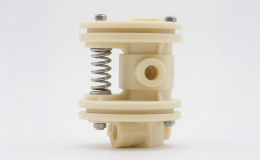

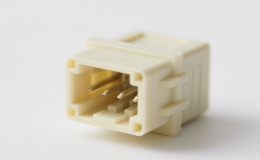

We provide precision CNC-machined PEEK parts for aerospace, medical, automotive, and industrial applications. With high strength, chemical resistance, and thermal stability up to 260°C, PEEK is ideal for demanding components like bearings, bushings, seals, and insulators.