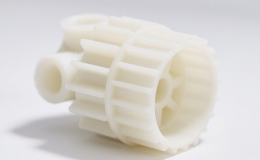

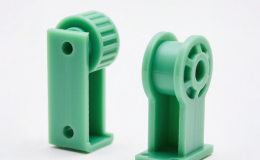

At REKO, we offer high-precision CNC machining of PA parts, ensuring tight tolerances and consistent quality for your custom plastic components.

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Property | Typical Value | Unit | Notes |

| Density | ~1.14 | g/cm³ | Lightweight material with good mechanical strength. |

| Water Absorption (24h) | PA6: ~1.8, PA66: ~1.3 | % | Can affect dimensional stability. |

| Tensile Strength (PA66) | ~80–85 | MPa | Strong tensile resistance under load. |

| Tensile Modulus (PA66) | ~3,200–3,500 | MPa | Indicates stiffness and rigidity. |

| Elongation at Break | ~7–50 (varies by grade) | % | Good flexibility, depending on grade. |

| Flexural Strength | ~110–125 | MPa | Resists deformation under bending. |

| Flexural Modulus | ~3,000–3,200 | MPa | Reflects resistance to flexural strain. |

| Compressive Strength | ~35–90 | MPa | Suitable for load-bearing components. |

| Hardness (Shore D) | ~80 | -- | Provides good surface resistance. |

| Impact Strength (Charpy) | ~7 | kJ/m² | Withstands sudden impacts. |

| Melting Point | ~218–260 | °C | Suitable for moderate-temperature applications. |

| Heat Deflection Temp (0.45 MPa) | ~150-170 | °C | Maintains shape under heat load. |

| Service Temperature | Up to ~100–110 | °C | Suitable for most industrial conditions. |

| Coefficient of Thermal Expansion | ~80–110 × 10⁻⁶/K | µm/m·°C | Dimensional changes with temperature. |

| Thermal Conductivity | ~0.3–0.4 | W/m·K | Low thermal conductivity, acts as an insulator. |

| Dielectric Constant (1 MHz) | ~3.6 | -- | Suitable for electrical insulation. |

| Surface Resistivity | ≥10¹²–10¹⁴ | Ω·cm | Excellent electrical insulation properties. |

As Machined The natural finish achieved through the machining process enhances the surface properties of PA(Nylon), making it suitable for use in its machined state. | Functional and structural components |

Sand Blasting This finish imparts a frosted or matte appearance to PA(Nylon), effectively reducing visible tool marks. | Aesthetic parts, visual housings |

Teflon Coating Teflon coating can be applied to PA(Nylon) to enhance wear resistance and reduces friction, beneficial in high-wear or sliding applications. | Bushings, sliders, moving assemblies |

Painting Nylon parts can be coated with paint for visual enhancement or protective finishes. Their slightly porous surface generally accepts paint better than many plastics,although using a primer is often recommended to ensure good adhesion. | Covers, non-load shellsCovers, non-load shells |

Powder Coating (Less Common) PA(Nylon) can be powder coated using specialized techniques, providing a durable and protective surface finish in various colors, although this is less common. | Customized industrial enclosures |

Due to moisture absorption and thermal limits, PA(Nylon) often requires surface preparation (e.g., drying, priming) before painting or coating.

We provide precision CNC machining services for Nylon (Polyamide), a versatile and durable engineering plastic known for its strength, wear resistance, and machinability. Below are recommended guidelines to achieve high-quality results. Actual settings may vary based on machine setup, tooling, and part design.

| Parameter | Recommended Range | Notes |

| Tooling | Carbide or HSS tools with sharp edges and positive rake (~10–15°); diamond‑coated inserts for filled Nylon | Sharp tools reduce friction and heat; polished flutes help evacuate chips and improve surface finish |

| Cutting Speed (SFM) | Unfilled Nylon: 500–1000 SFM. Glass‑filled Nylon: 300–600 SFM | Higher speeds help reduce heat; reduce speed for abrasive grades |

| Feed per Tooth / Rev | Roughing: 0.10–0.30 mm/rev (0.004–0.012"); Finishing: 0.08–0.20 mm/rev (0.003–0.008") | Faster feeds minimize heat accumulation; reduce feed for filled materials |

| Depth of Cut (DOC) | Rough: 2–5 mm; Finish: 0.5–1 mm | Multiple light passes improve surface quality and dimensional accuracy |

| Cooling / Chip Control | Dry machining with compressed air or mist coolant; frequent chip evacuation | Avoid moisture-induced swelling; Prevent chip recutting and surface blemishes |

| Machining Strategy | Climb milling, high-helix tools, adaptive clearing | Minimizes heat and tool pressure, improves finish |

| Pre‑Drying Material | Dry Nylon at ~65 °C for 12–16 hours to below ~0.2% moisture content | Prevents dimensional changes during machining |

| Fixturing | Use soft jaws or vacuum holding; avoid over‑clamping | Prevents deformation, especially in thin geometriesPrevents deformation, especially in thin geometries |

| Tolerances / Surface Finish | Standard: ±0.05 mm; Precision: ±0.02 mm or better with controlled conditions | Consistent results on tough, wear-resistant components |

Our CNC-machined Nylon (PA6 / PA66) components deliver precision, durability, and versatility across industries—including automotive, industrial machinery, electronics, and consumer products. With a great strength-to-weight ratio and outstanding wear resistance, nylon is ideal for structurally demanding and motion-intensive parts.