Why Sensor Components require high-precision CNC machining?

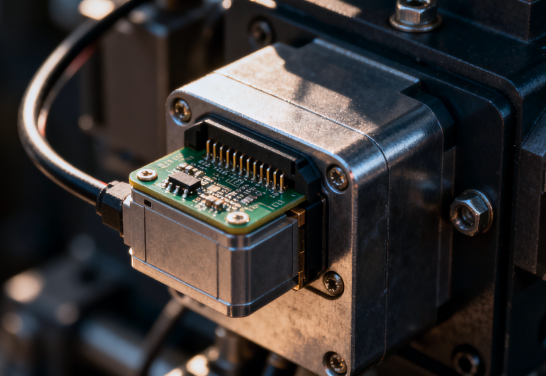

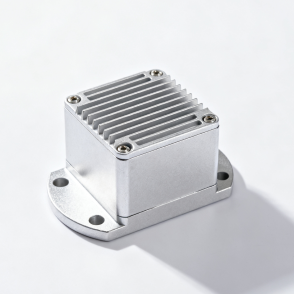

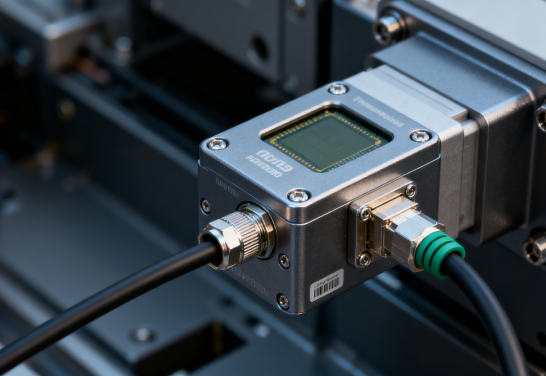

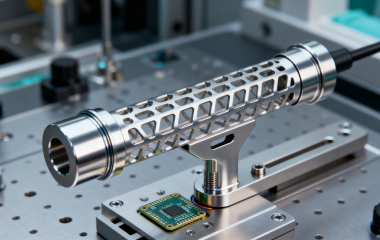

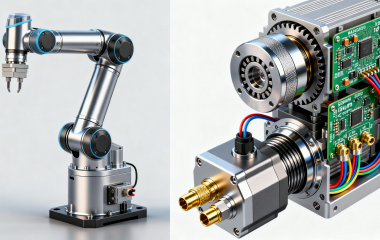

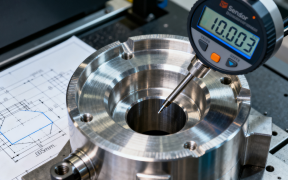

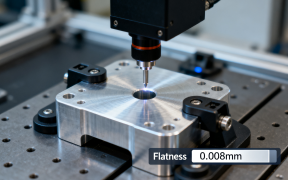

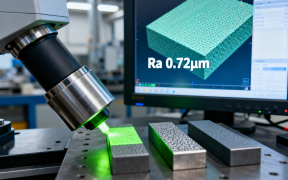

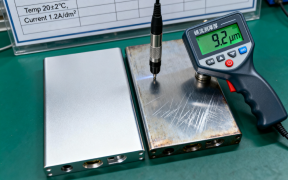

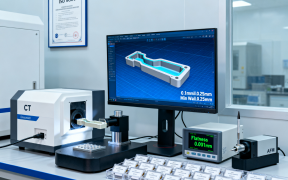

Sensor components are often compact, complex, and require micron-level precision to ensure accurate signal detection and environmental durability.

At Reko, we specialize in machining miniature housings, connectors, and mechanical structures for various sensors — guaranteeing consistent accuracy and stability under harsh conditions.