CNC Machining Service for Automotive Industry

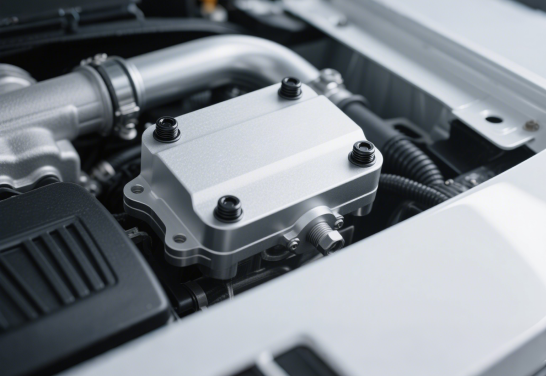

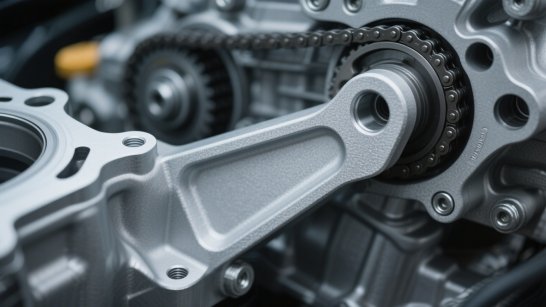

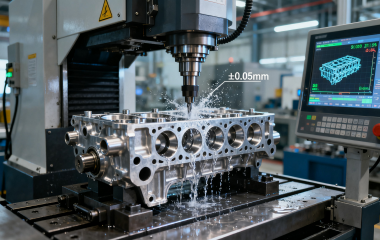

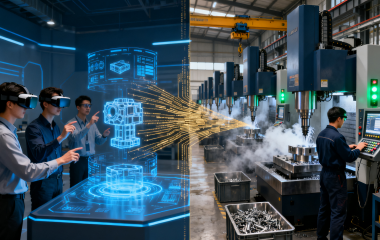

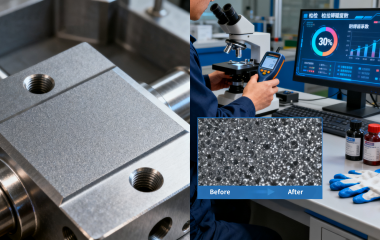

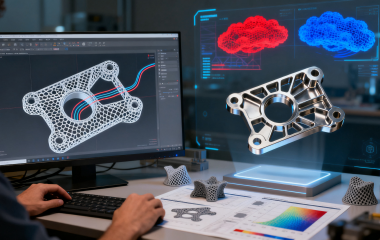

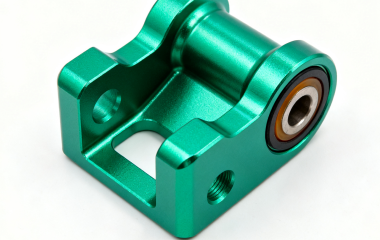

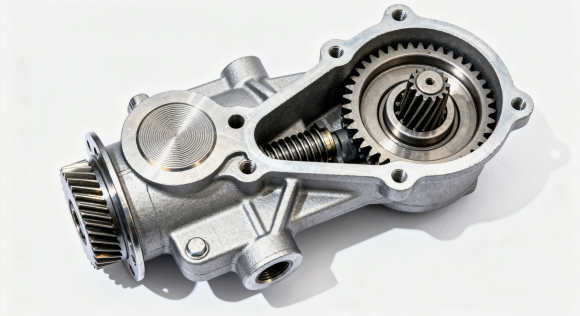

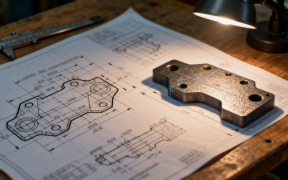

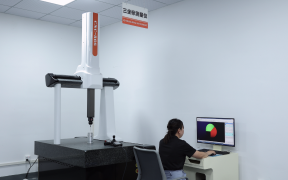

The automotive industry demands high-precision, durable, and safety-critical components. From engines and transmissions to suspension, braking, and exhaust systems, every part must meet strict standards for reliability and performance.

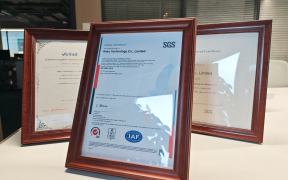

With over a decade of certified experience, REKO provides high-quality parts that meet exact specifications—from large production runs to specialized custom projects.