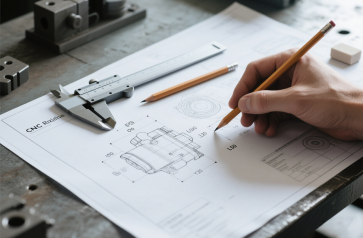

1. CAD Design Development

Our process begins with the development of a detailed 3D model using advanced computer-aided design (CAD) software. This model defines all geometric features, dimensional tolerances, hole placements, threads, and surface finishes. We ensure that the design is optimized for machinability and functionality based on the intended application.

2. CAM Programming & G-Code Generation

Once the CAD model is finalized, it is imported into CAM (Computer-Aided Manufacturing) software to create the machining strategy. Tool paths are generated based on material type, cutting tool specifications, and machining operations (e.g., roughing, finishing, drilling, contouring). The CAM software then converts these instructions into G-code — the standardized machine language used by CNC systems — detailing tool movements, spindle speeds, feed rates, and coordinates.

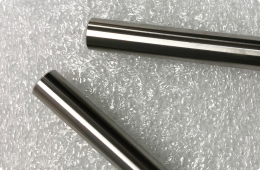

3. Machine Configuration & Setup

Our CNC operators prepare the machine according to the G-code instructions: · Selection and installation of suitable cutting tools (e.g., end mills, face mills, drills) · Securing the raw material (workpiece) on the machine bed using precision vises, fixtures, or vacuum systems · Loading the G-code into the CNC controller · Setting zero points (work offsets) and performing dry runs to verify paths

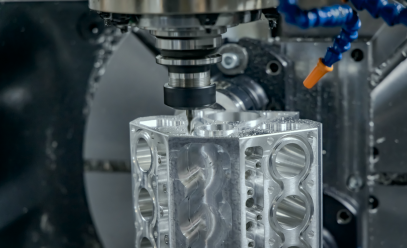

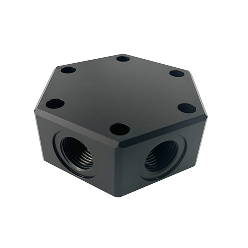

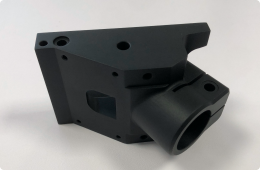

4. Precision Milling Execution

The CNC machine executes the programmed instructions, moving the cutting tool with micron-level accuracy along multiple axes (typically 3, 4, or 5 axes depending on part complexity). Material is progressively removed through a series of operations, including: · Rough milling for bulk material removal · Semi-finishing to refine geometry · Finishing cuts to achieve final dimensions and surface finish Advanced sensors and control systems maintain stability, compensate for tool wear, and ensure thermal consistency throughout the process.

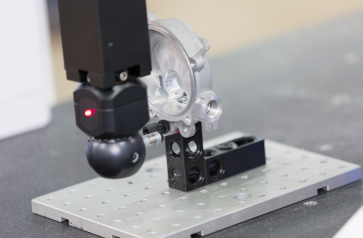

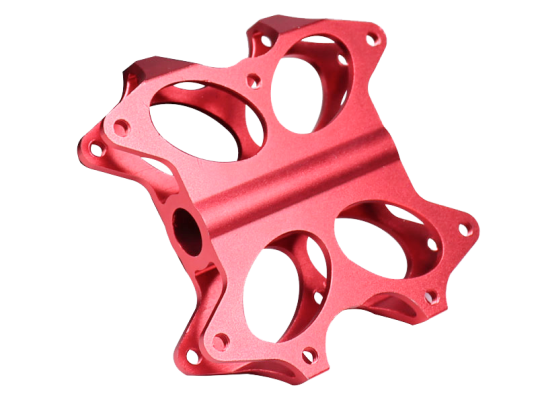

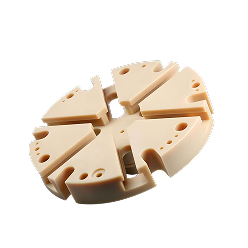

5. Quality Inspection & Finishing

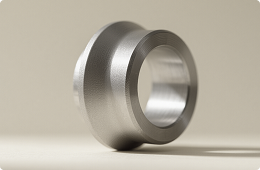

After machining, each component undergoes rigorous quality inspection using precision measuring tools such as calipers, micrometers, CMM (Coordinate Measuring Machines), and surface roughness testers. Depending on customer requirements.Additional processes like deburring, polishing, or surface treatments may be applied to meet final product specifications.

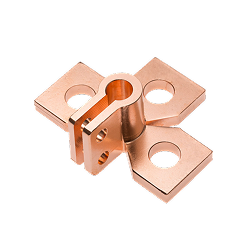

As Machined

As Machined  Bead Blast

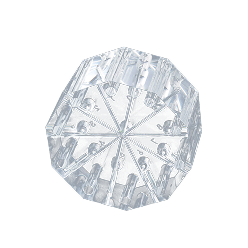

Bead Blast  Polishing

Polishing  Anodizing

Anodizing  E-Coating

E-Coating  Heat Treatment

Heat Treatment  Brushed Finish

Brushed Finish  Powder Coating

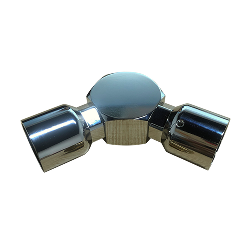

Powder Coating  Plating

Plating  Painting

Painting  Passivation

Passivation  Laser Engraving/CNC engraving

Laser Engraving/CNC engraving