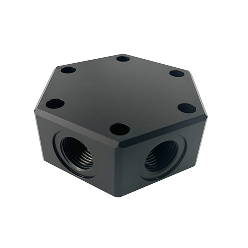

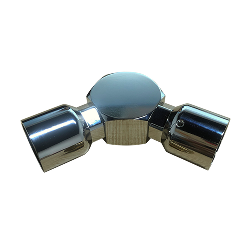

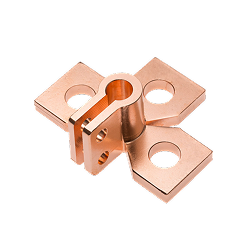

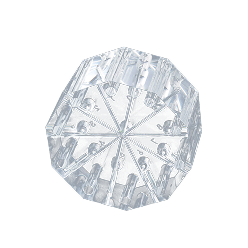

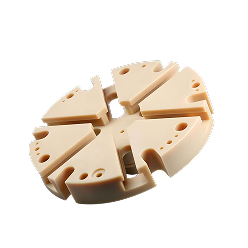

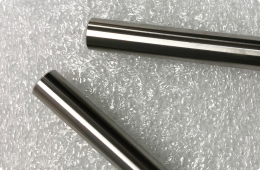

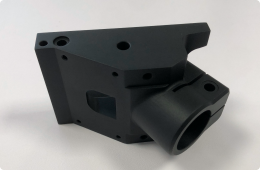

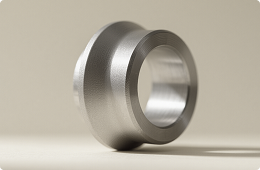

Aluminum: Aluminum is known for its lightweight, strength, and machinability, making it an ideal choice for a wide range of applications, including aerospace, automotive, and industrial parts. Its excellent corrosion resistance also makes it perfect for outdoor projects and structural components.

Alloys: Aluminum 6061-T6, Aluminum 7075-T6, Aluminum 5052, Aluminum 5083,Aluminum 6060,Aluminum 6063,Aluminum 6082, Aluminum 2017

Available Finish: As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

As Machined

As Machined  Bead Blast

Bead Blast  Polishing

Polishing  Anodizing

Anodizing  E-Coating

E-Coating  Heat Treatment

Heat Treatment  Brushed Finish

Brushed Finish  Powder Coating

Powder Coating  Plating

Plating  Painting

Painting  Passivation

Passivation  Laser Engraving/CNC engraving

Laser Engraving/CNC engraving