Technical Advantages of Powder Coating

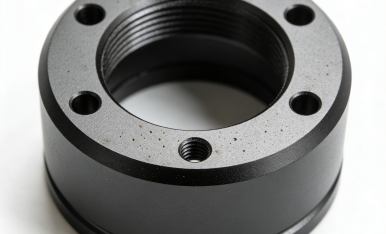

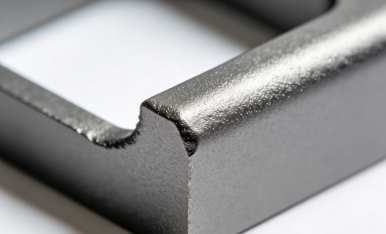

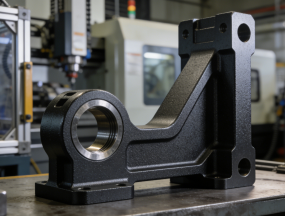

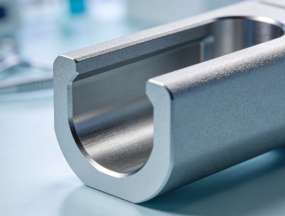

Smooth & Uniform Finish

Powder flows and levels during curing for a consistent texture.

Excellent Corrosion Resistance

Protects metal surfaces from moisture, chemicals, and oxidation.

Strong Impact & Scratch Resistance

Ideal for parts requiring durability.

Environmentally Friendly

Contains no solvents or VOC emissions.

Wide Color & Texture Options

Available in RAL colors, matte, gloss, metallic, textured finishes.