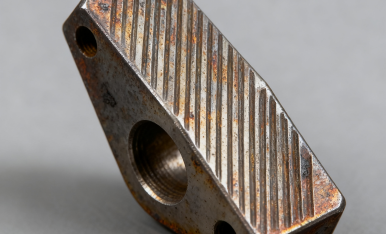

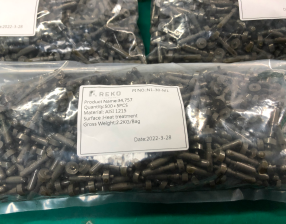

Improve strength, hardness, wear resistance, and fatigue life with precision-controlled heat treatment processes designed for CNC-machined components.

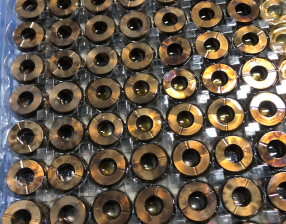

Heat treatment is a controlled thermal process that changes the mechanical properties of metals—such as hardness, strength, toughness, and ductility—without altering their overall shape.

Heat treatment can be applied before machining, after machining, or as a final strengthening step, depending on material and performance requirements.

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

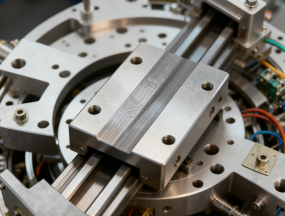

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| 01 | Heating Controlled furnace heating to reach target temperature Notes: (Ensures uniform metallurgical transformation) Standards: In-house HT-SOP-01; | Standards: In-house HT-SOP-01; |  |

| 02 | Holding (Soaking) Maintaining temperature for a specific duration Notes: (Allows complete structural change) Standards: In-house HT-SOP-02; | Standards: In-house HT-SOP-02; |  |

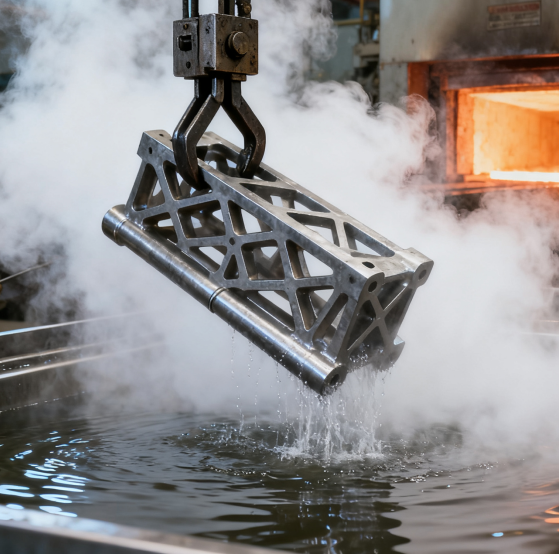

| 03 | Cooling / Quenching Air, oil, water, or gas cooling based on material & requirements Notes: (Determines hardness level) Standards: In-house HT-SOP-03; | Standards: In-house HT-SOP-03; |  |

| 04 | Tempering / Stress Relief Secondary heating to reduce brittleness and stabilize properties Notes: (Achieves ideal balance of hardness & ductility) Standards: In-house HT-SOP-04; | Standards: In-house HT-SOP-04; |  |

| 05 | Inspection Hardness testing, deformation measurement, metallographic analysis Notes: (Ensures the part meets performance standards) Standards: In-house HT-SOP-05; | Standards: In-house HT-SOP-05; |  |

| 06 | Final Machining / Surface Finishing Optional: grinding, polishing, anodizing, coating Notes: (Ensures assembly accuracy and appearance quality) Standards: In-house HT-SOP-06; | Standards: In-house HT-SOP-06; |  |

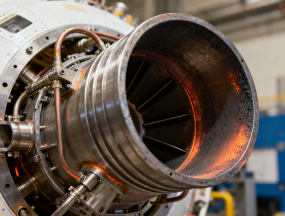

Heat treatment increases fatigue life for brackets, housings, and structural parts.

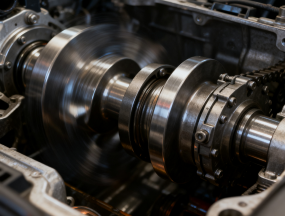

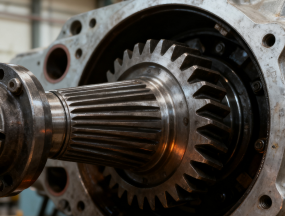

Gears, shafts, pistons, and powertrain components require high toughness and wear resistance.

Axles, hubs, sprockets, pedals—improved durability under dynamic load.

Tooling, fixtures, hydraulic components, and high-pressure fittings.

Avoid placing critical tight-tolerance features on areas expected to deform during heat treatment;

Add machining allowance to compensate for thermal deformation;

Avoid sharp corners and sudden wall-thickness transitions;

Clarify the required hardness range on the drawing;

Specify critical surfaces or areas that must NOT be hardened;

For complex shapes, 3D models or samples are recommended before mass production;

Typical heat treatment parameters for CNC machined parts:

| Parameter | Typical Range | Description |

| Hardness Range | HRC 20–65 (depending on material) | Final hardness after quenching/tempering |

| Heat Treatment Temperature | 500–1,100°C | Typical heating temperature range for common metals |

| Cooling Method | Air / Oil / Water / Gas | Different cooling media affect hardness and distortion |

| Dimensional Change | ±0.05–0.3 mm | Possible dimensional variation during heat treatment |

| Case Depth | 0.1–2.0 mm | Depth of surface hardening (carburizing / nitriding) |

| Material Compatibility | Steel / Alloy Steel / Stainless Steel / Tool Steel | Applicable materials for heat treatment processes |

For parts requiring high-precision assembly, it is recommended to perform heat treatment before grinding, milling, or turning critical dimensions.

For easily deformable thin-walled structures, vacuum heat treatment or gas quenching should be used to reduce deformation.

Send us your part files or design drawings. Our surface finishing experts will evaluate the part geometry, surface requirements, and production volume and recommend the ideal machining process for your CNC machined parts.