DFM Design Guidelines

To achieve the best appearance:

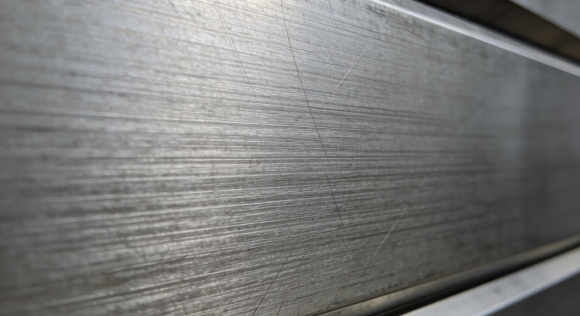

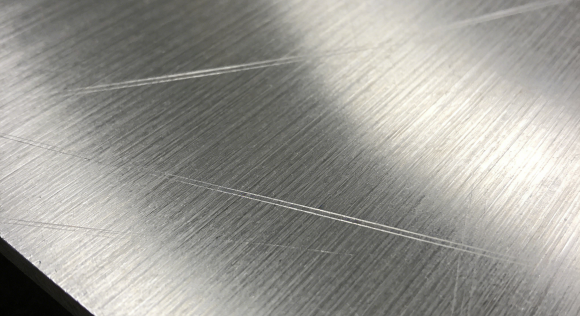

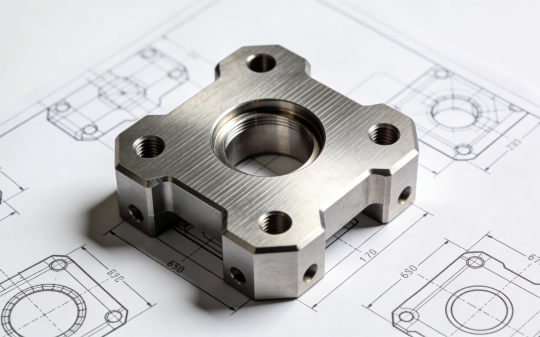

Avoid deep machining marks or tool chatter

Maintain consistent surface flatness

Large surfaces require uniform material removal

Avoid sudden height transitions

Prefer brushing direction parallel to longest side