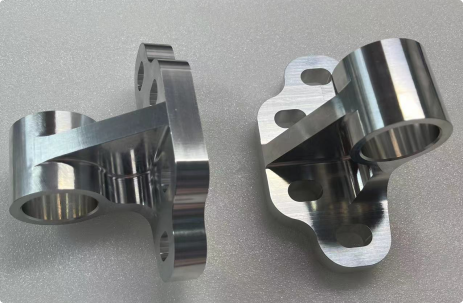

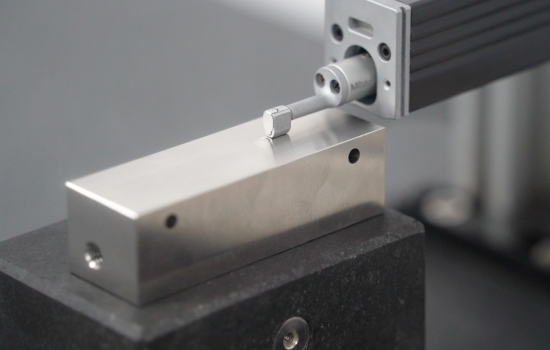

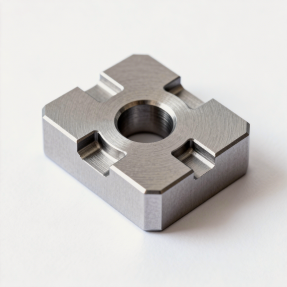

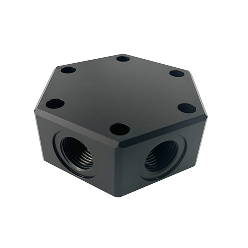

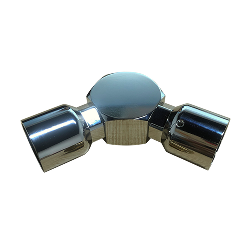

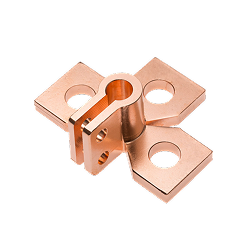

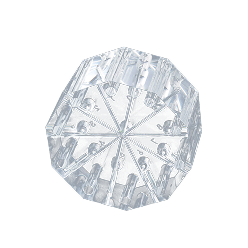

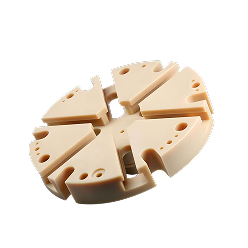

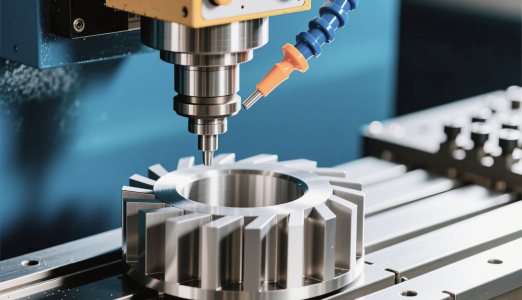

Surface Quality & Roughness

Typical surface roughness ranges from Ra 1.6–3.2 μm, providing a reliable balance between appearance, performance, and cost. While not intended for cosmetic applications, the finish delivers the precision and consistency required for engineering, mechanical, and assembly components.

Surface uniformity may vary slightly depending on: