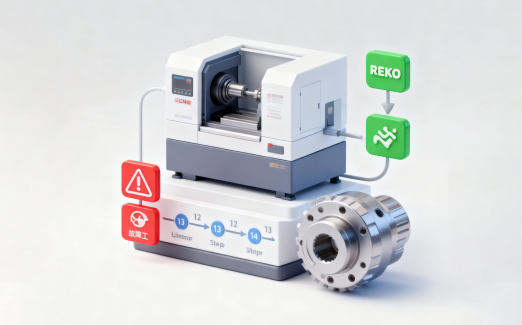

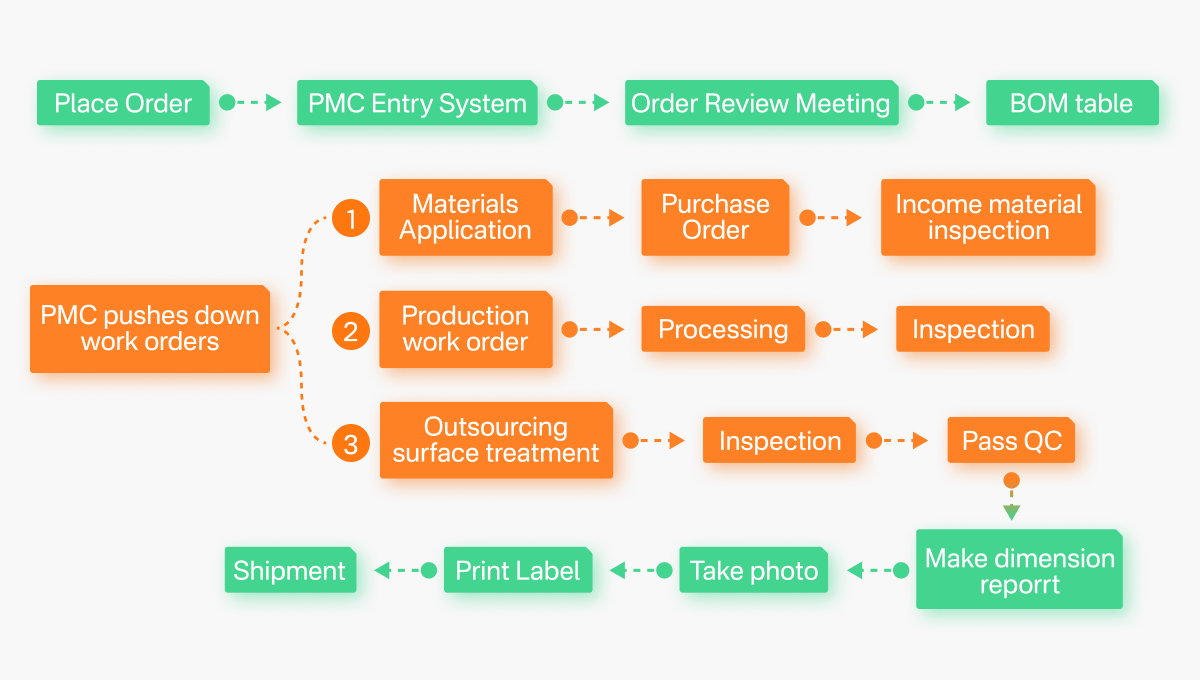

Precision in CNC machining doesn't come from machines alone—it comes from a disciplined and repeatable process.

REKO's 13-step production workflow ensures your parts are made the right way, every time.

Many customers chose us because we solved problems that other suppliers ignored—problems that caused delays, failures, and costly rework.

Below is the fully structured English version you can place directly on your website.

Conduct DFM review, tolerance analysis, risk assessment, and process planning.

Prevents misunderstanding, reduces rework, and ensures feasibility before machining.

Previous suppliers skipped this step, leading to deformation, poor tolerance control, or design misinterpretation.

Clients told us: "REKO was the first supplier who actually helped us optimize our design."

Purchase certified materials, record batch numbers, and maintain traceable material inventory.

Material quality determines machining performance, finishing quality, and structural stability.

Incorrect materials, inconsistent hardness, and unstable surface treatment results with other suppliers.

Check dimensions, hardness, material reports, and isolate nonconforming batches.

Defective materials can cause hidden risks or full-batch failure later in production.

Suppliers skipped incoming inspection → resulting in porosity, mixed materials, or low strength.

Professional CAM programming, toolpath simulation, collision avoidance, and deformation control.

Accuracy, surface quality, and efficiency depend on correct programming logic.

Improper toolpaths caused tool marks, overcutting, broken edges, and assembly issues.

Use branded cutting tools, track tool life, and select tools based on tolerance and material type.

Tool condition directly impacts surface roughness and precision consistency.

Cheap tools caused burrs, inconsistent dimensions, and unstable quality.

Use probing systems to measure tool length, compensate tool wear, and ensure repeatable precision.

Keeps accuracy stable during long machining cycles.

Manual tool setting led to size variation and shape deviation in batch production.

Perform multi-axis machining, control temperature, optimize clamping force, and prevent deformation.

Determines dimensional stability, surface quality, and part performance.

Thin-wall parts were deformed, tolerance drifted, or surfaces showed heavy tool marks.

First-article inspection, sampling inspection, and critical tolerance verification during production.

Catches deviations early and prevents batch defects.

Other suppliers only inspected at the final stage → causing large-scale failures.

Full inspection using CMM, height gauges, micrometers, projectors, and custom gauges. FAI and PPAP reports available.

High-precision parts require high-precision measurement.

Reports from previous suppliers were incomplete, unprofessional, or inaccurate.

Before anodizing, plating, or sandblasting, we check every part for:

Surface treatment amplifies flaws—small scratches can turn into visible defects after finishing.

Suppliers sent parts to finishing without checking → leading to color difference, rough surfaces, and full-batch rework.

We identify risks before finishing, preventing costly scrap.

Perform anodizing, plating, blasting, polishing, and other finishing processes with trusted partners, while our QC team monitors every batch.

A consistent finish is critical for appearance, corrosion resistance, and assembly functionality.

Color inconsistency, thickness deviation, and surface defects were common with previous vendors.

100% appearance check, critical tolerance re-verification, cleaning, and surface inspection after finishing.

Ensures parts look perfect and are ready for assembly.

Received scratched parts, dirty surfaces, or mixed batches.

Improper packaging causes scratches, dents, and damage during transit.

Suppliers used thin bags, causing parts to collide and get damaged.

Full process traceability ensures every part is tracked, verified, and accountable from raw material to final delivery.

Every step of our workflow exceeds industry standards, not just meets them.

We proactively detect risks early and communicate with customers before issues escalate.

Over 10 years serving global markets gives us a deep understanding of international expectations and quality norms.