Why We Implement Gauge Management

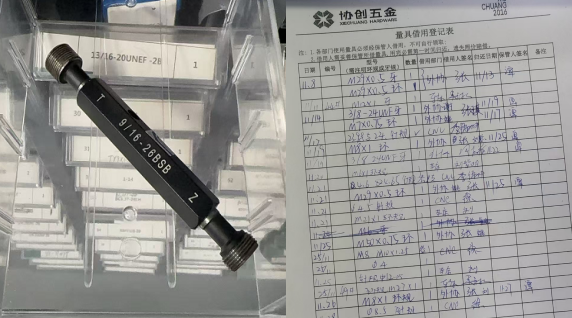

In precision machining, gauges are essential tools to ensure dimensional consistency, improve inspection efficiency, and reduce production risks.

In precision machining, gauges are essential tools to ensure dimensional consistency, improve inspection efficiency, and reduce production risks.

Calibration is performed by certified third-party laboratories or qualified internal personnel.

1. Quality department unified management.

2. Production department needs to write an application form to borrow (self-inspection products during production process)

3. Purchasing department needs to write an application form to borrow (give to oxidation plant for inspection)

4. 3D and 2.5D are calibrated once a month. (calibrated by internal staff)

5. Calipers are calibrated once a year (calibrated by third-party inspection company)

At REKO, all precision measuring tools are sent to certified third-party laboratories for regular calibration to ensure accuracy, reliability, and traceability. Each tool is managed under a strict calibration cycle to prevent measurement deviation and maintain consistent quality standards.

Measuring Tool:Caliper

Brand Name:MITUTOYO

Calibration Frequency:Once per year

This caliper will receive a complete calibration report and certification, and the results will be recorded in our measurement tool system for traceability.

A gauge must be retired if any of the following apply: