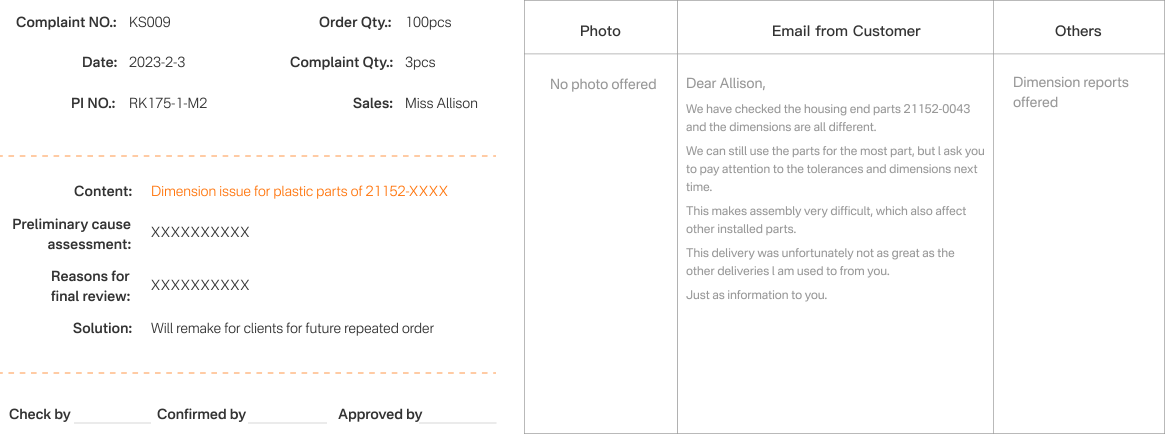

1. Information reception:

Complaint received → Sales or support team records and confirms details.

2. Problem Analysis:

Engineering and QC jointly analyze the root cause.

3. Corrective action:

Corrective actions are planned and implemented.

4. Results feedback:

Investigation results and improvements are shared with the client.

5. Preventive measures:

reventive actions are documented to avoid recurrence.

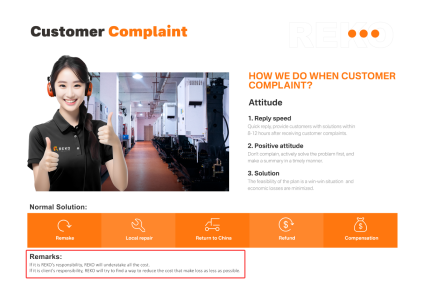

Remake

Remake  Local repair

Local repair  Return to China

Return to China  Refund

Refund  Compensation

Compensation