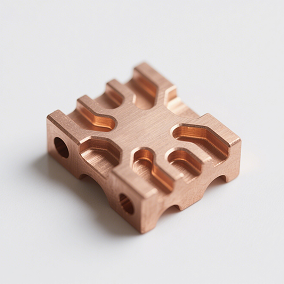

High-conductivity copper components for electronics, heat exchangers, and custom industrial parts.

Tolerance down to 0.0005 inches(0.01mm)

No minimum order quantity

Over 40 Certified Materials

Delivery in as little as 5 days

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Alloy | Temp Resistance (°C) | Hardness (HB) | Cost | Common Applications | Surface Treatment Limitations | Key Features |

| C10100 | ~200 | ~40 | $$$$ | High-end electronics, vacuum tubes, semiconductors | Easily oxidized, not ideal for anodizing | Highest purity (99.99%+), excellent electrical conductivity |

| C11000 (T2) | ~200 | ~50 | $$$ | Electrical connectors, busbars, heat exchangers | Cannot be anodized, surface oxidizes | High conductivity, ductile, good thermal transfer |

| C12200 | ~200 | ~50 | $$$ | Plumbing, HVAC, weldable parts | Not suitable for decorative finishes | Good corrosion resistance, excellent weldability |

| C14500 | ~200 | ~60 | $$$$ | Machined electrical parts, connectors | Limited polishing shine | Excellent machinability, retains conductivity |

| C17200 | ~315 | ~100–140 | $$$$ | Aerospace, tooling, heavy-duty springs | Requires caution due to toxicity in dust | High strength, wear resistance, corrosion resistance |

Polishing High-gloss, mirror-like surface ideal for decorative or sanitary components. | Easily scratched, no corrosion protection. | C10100, C11000 |

Electroplating Nickel, gold, or silver plating improves corrosion resistance and visual appeal. | Requires thorough cleaning and uniform base finish. | C10100, C11000, C14500 |

Painting / Powder Coating Adds color, surface protection, and enhanced durability. | May reduce electrical/thermal conductivity. | C11000, C12200 |

Passivation Chemical treatment enhances resistance to atmospheric oxidation. | Less effective than on stainless steel. | C12200, C14500 |

REKO offers high-precision CNC machining services for copper parts, from prototyping to large-scale production. Our copper components are trusted across industries such as electronics, telecommunications, energy systems, medical devices, and high-end architectural applications — where exceptional electrical/thermal conductivity, corrosion resistance, and precise tolerances are essential.