Choose the Right Material, Build with Confidence.

Tolerance down to 0.0005 inches(0.01mm)

No minimum order quantity

Over 40 Certified Materials

Delivery in as little as 5 days

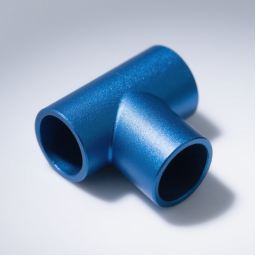

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

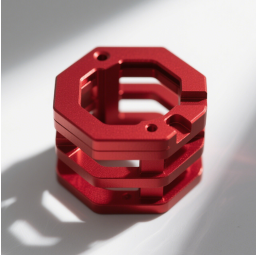

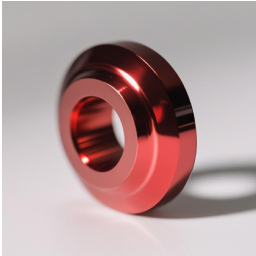

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Alloy | Temp Resistance (°C) | Hardness (HB) | Cost | Common Applications | Surface Treatment Limitations | Key Features |

| 6061-T6 | ~150°C (Peak 250°C) | 95 | $$$ | Automotive, Aerospace, Structural Parts | Poor anodizing for black coloring | Versatile, good corrosion resistance, moderate strength |

| 7075-T6 | ~120°C (Peak ~200°C) | 150 | $$$$ | Aerospace, Defense, Racing | Not weldable, limited electroplating | Very high strength, low weldability, lower corrosion resistance |

| 5052 | ~65–100°C | 60-70 | $$ | Marine, Automotive Panels, Enclosures | None significant | Excellent corrosion resistance, great formability and weldability |

| 5083 | ~65–100°C | 75–85 | $$$ | Marine, Pressure Vessels | Not suitable for high-heat welding | Superior saltwater resistance, ideal for harsh environments |

| 6060 | ~150°C | 60 | $$ | Architecture, Appliances | Lower strength not for high-load parts | Good extrudability, great surface finish |

| 6063 | ~150°C | 55–60 | $$ | Decorative Frames, Windows | Excellent for anodizing and dyeing | Aesthetic finish, corrosion-resistant, lower strength |

| 6082 | ~150°C | 95–100 | $$$ | Construction, Transport, Bridges | Poor small-radius bending | High strength and corrosion resistance, European standard choice |

| 2017 | ~120°C | 105 | $$$$ | Aerospace Fittings, Structural Parts | Poor weldability, weak corrosion resistance | High strength, good machinability, responsive to heat treatment |

Anodizing Increases corrosion resistance, improves appearance | May not be uniform on complex geometries. | 6061, 5052, 6063, 6082 |

Bead blasting Creates a matte or satin texture | Slight surface erosion, not protective alone. | All aluminum alloys |

Polishing For high-gloss or reflective parts | Surface is prone to scratches, not protective. | 6061, 6063 |

Chromate coating Adds light corrosion protection | Limited wear resistance, not decorative. | 5052, 6061, 7075 |

Painting or Powder Coating Improves durability and color | Adds thickness, not ideal for tight tolerance features. | Most alloys, especially 6061, 5052 |

REKO specializes in rapid CNC machining for both prototyping and high-volume production. We serve global clients across industries such as aerospace, automotive, motorcycles, medical devices, energy exploration, telecommunications, robotics, and more — delivering precision parts with reliable quality and fast turnaround.