| h1 | js1 | |||||||||||||||||||||||||||

| h2 | js2 | |||||||||||||||||||||||||||

| h3 | js3 | |||||||||||||||||||||||||||

| g4 | h4 | js4 | k4 | m4 | n4 | p4 | r4 | s4 | ||||||||||||||||||||

| f5 | g5 | h5 | j5 | js5 | k5 | m5 | n5 | p5 | r5 | s5 | t5 | u5 | v5 | x5 | y5 | z5 | ||||||||||||

| e6 | f6 | g6 | h6 | j6 | js6 | k6 | m6 | n6 | p6 | r6 | s6 | t6 | u6 | v6 | x6 | y6 | z6 | |||||||||||

| d7 | e7 | f7 | g7 | h7 | j7 | js7 | k7 | m7 | n7 | p7 | r7 | s7 | t7 | u7 | v7 | x7 | y7 | z7 | ||||||||||

| c8 | d8 | e8 | f8 | g8 | h8 | js8 | k8 | m8 | n8 | p8 | r8 | s8 | t8 | u8 | v8 | x8 | y8 | z8 | ||||||||||

| a9 | b9 | c9 | d9 | e9 | f9 | h9 | js9 | |||||||||||||||||||||

| a10 | b10 | c10 | d10 | e10 | h10 | js10 |

| |||||||||||||||||||||

| a11 | b11 | c11 | d11 | h11 | js11 | |||||||||||||||||||||||

| a12 | b12 | c12 | h12 | js12 | ||||||||||||||||||||||||

| a13 | b13 | c13 | h13 | js13 | ||||||||||||||||||||||||

| H1 | Js1 | |||||||||||||||||||||||||||

| H2 | Js2 | |||||||||||||||||||||||||||

| H3 | Js3 | |||||||||||||||||||||||||||

| H4 | Js4 | K4 | M4 | |||||||||||||||||||||||||

| G5 | H5 | Js5 | K5 | M5 | N5 | P5 | R5 | S5 | ||||||||||||||||||||

| F6 | G6 | H6 | J6 | Js6 | K6 | M6 | N6 | P6 | R6 | S6 | T6 | U6 | V6 | X6 | Y6 | Z6 | ||||||||||||

| D7 | E7 | F7 | G7 | H7 | J7 | Js7 | K7 | M7 | N7 | P7 | R7 | S7 | T7 | U7 | V7 | X7 | Y7 | Z7 | ||||||||||

| C8 | D8 | E8 | F8 | G8 | H8 | J8 | Js8 | K8 | M8 | N8 | P8 | R8 | S8 | T8 | U8 | V8 | X8 | Y8 | Z8 | |||||||||

| A9 | B9 | C9 | D9 | E9 | F9 | H9 | Js9 | N9 | P9 | |||||||||||||||||||

| A10 | B10 | C10 | D10 | E10 | H10 | Js10 |

| |||||||||||||||||||||

| A11 | B11 | C11 | D11 | H11 | Js11 | |||||||||||||||||||||||

| A12 | B12 | C12 | H12 | Js12 | ||||||||||||||||||||||||

| H13 | Js13 | |||||||||||||||||||||||||||

| Basic Hole | Shaft | |||||||||||||||||||||||||||

| a | b | c | d | e | f | g | h | js | k | m | n | p | r | s | t | u | v | x | y | z | ||||||||

| Clearance Fit | Transition Fit | Interference Fit | ||||||||||||||||||||||||||

| H6 | H6 f5 | H6 g5 | H6 h5 | H6 js5 | H6 k5 | H6 m5 | H6 n5 | H6 p5 | H6 r5 | H6 s5 | H6 t5 | |||||||||||||||||

| H7 | H7 f6 | H7 g6 | H7 h6 | H7 js6 | H7 k6 | H7 m6 | H7 n6 | H7 p6 | H7 r6 | H7 s6 | H7 t6 | H7 u6 | H7 v6 | H7 x6 | H7 y6 | H7 z6 | ||||||||||||

| H8 | H8 e7 | H8 f7 | H8 g7 | H8 h7 | H8 js7 | H8 k7 | H8 m7 | H8 n7 | H8 p7 | H8 r7 | H8 s7 | H8 t7 | H8 u7 | |||||||||||||||

| H8 d8 | H8 e8 | H8 f8 | H8 h8 |

| ||||||||||||||||||||||||

| H9 | H9 c9 | H9 d9 | H9 e9 | H9 f9 | H9 h9 | |||||||||||||||||||||||

| H10 | H10 c10 | H10 d10 | H10 h10 | |||||||||||||||||||||||||

| H11 | H11 a11 | H11 b11 | H11 c11 | H11 d11 | H11 h11 | |||||||||||||||||||||||

| H12 | H12 b12 | H12 h12 | ||||||||||||||||||||||||||

| Basic Shaft | Hole | ||||||||||||||||||||||||||||

| A | B | C | D | E | F | G | H | Js | K | M | N | P | R | S | T | U | V | X | Y | Z | |||||||||

| Clearance Fit | Transition Fit | Interference Fit | |||||||||||||||||||||||||||

| h5 | F6 h5 | G6 h5 | H6 h5 | Js6 h5 | K6 h5 | M6 h5 | N6 h5 | P6 h5 | R6 h5 | S6 h5 | T6 h5 | ||||||||||||||||||

| h6 | F7 h6 | G7 h6 | H7 h6 | Js7 h6 | K7 h6 | M7 h6 | N7 h6 | P7 h6 | R7 h6 | S7 h6 | T7 h6 | U7 h6 | |||||||||||||||||

| h7 | E8 h7 | F8 h7 | G8 h7 | H8 h7 | Js8 h7 | K8 h7 | M8 h7 | N8 h7 | |||||||||||||||||||||

| h8 | D8 h8 | E8 h8 | F8 h8 | H8 h8 |

| ||||||||||||||||||||||||

| h9 | D9 h9 | E9 h9 | F9 h9 | H9 h9 | |||||||||||||||||||||||||

| h10 | D10 h10 | H10 h10 | |||||||||||||||||||||||||||

| h11 | A11 h11 | B11 h11 | C11 h11 | D11 h11 | H11 h11 | ||||||||||||||||||||||||

| h12 | B12 h12 | H12 h12 | |||||||||||||||||||||||||||

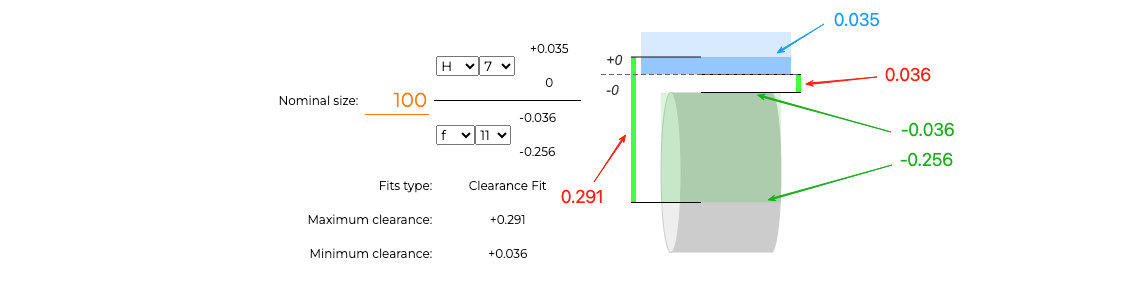

| Nominal size: | | ||

| | |||

| Fits type: | |||

| Maximum clearance: | |||

| Minimum clearance: | |||

The Fits and Tolerance Calculator is a powerful tool designed to calculate hole and shaft limits and fits according to the ISO 286 standard (works in line with ISO 286-1 (2010), ISO 286-2 (2010)), This standard provides a systematic approach to specifying tolerances and fits for linear dimensions, particularly for holes and shafts. The calculator simplifies the process for engineers and designers, helping them determine the appropriate tolerances and fits to ensure interchangeability and functionality of mechanical components.

Nominal size: The intended size of a part as specified in the technical drawings.

Tolerance: The permissible variation from the nominal size.

Deviation: The difference between the actual size and the nominal size.

Upper Deviation: The difference between the maximum limit size and the nominal size.

Lower Deviation: The difference between the minimum limit size and the nominal size.

Fit: The relationship between a hole and a shaft when assembled.

Nominal size: Enter the nominal size of the hole or shaft in millimeters.

Hole Tolerance: Select the tolerance class for the hole (e.g., H7). The tolerance class is designated by a letter (for fundamental deviation) and a number (for tolerance grade).

Shaft Tolerance: Select the tolerance class for the shaft (e.g., h7).

Designation: The tolerance class designation for the hole (e.g., H7).

Hole Upper Deviation: The maximum deviation of the hole from the nominal size.

Hole Lower Deviation: The minimum deviation of the hole from the nominal size.

Maximum Hole Size: The largest permissible size of the hole.

Minimum Hole Size: The smallest permissible size of the hole.

Designation: The tolerance class designation for the shaft (e.g., h7).

Shaft Upper Deviation: The maximum deviation of the shaft from the nominal size.

Shaft Lower Deviation: The minimum deviation of the shaft from the nominal size.

Maximum Shaft Size: The largest permissible size of the shaft.

Minimum Shaft Size: The smallest permissible size of the shaft.

Designation: The fit type (e.g., clearance, transition, or interference).

Fit Type: Describes whether the fit is clearance, transition, or interference.

Maximum Clearance/Interference: The largest possible clearance or interference between the hole and shaft.

Minimum Clearance/Interference: The smallest possible clearance or interference between the hole and shaft.

Ensure Accuracy: Make sure the Nominal size entered is within the range supported by the calculator (typically up to 3150 mm).

Experiment with Tolerance Classes: Use the calculator to experiment with different tolerance classes to understand their impact on fit and clearance.

Verify Results: Always verify the results with relevant standards and engineering guidelines, as the calculator provides a general analysis.

The ISO 286 Fit Calculator is an essential tool for engineers and designers working with mechanical components. By following the steps outlined above, users can quickly determine the appropriate tolerances and fits for holes and shafts, ensuring that parts are designed to meet functional and interchangeability requirements.