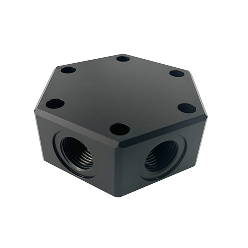

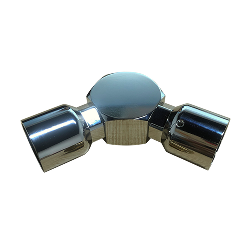

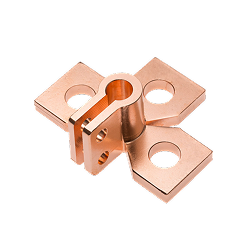

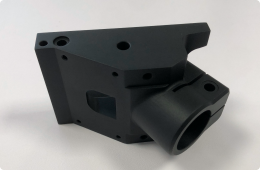

Алюминий:Алюминий известен своей легкой, прочностью и оборудованием, что делает его идеальным выбором для широкого спектра применений, включая аэрокосмическую, автомобильную и промышленную детали.

Сплавы:Алюминий 6061-T6, алюминий 7075-T6, алюминий 5052, алюминий 5083, алюминий 6060, алюминий 6063, алюминий 6082, алюминий 2017

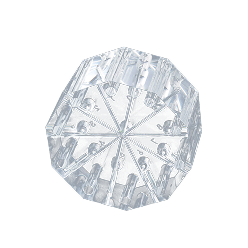

Доступная отделка:В качестве обработки, анодирования, порошкового покрытия, гальванизации, рисования, песчаных промышленности, полировки

Как обработано

Как обработано  Bead Blast

Bead Blast  Полировка

Полировка  Анодирование

Анодирование  E-Coating

E-Coating  Термическая обработка

Термическая обработка  Почистить отделку

Почистить отделку  Порошковое покрытие

Порошковое покрытие  Покрытие

Покрытие  Рисование

Рисование  Пассивация

Пассивация  Лазерная гравюра/Гравирование ЧПУ

Лазерная гравюра/Гравирование ЧПУ