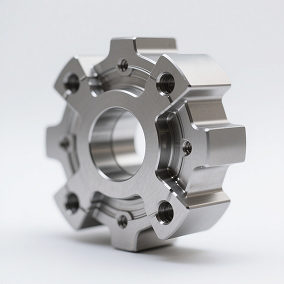

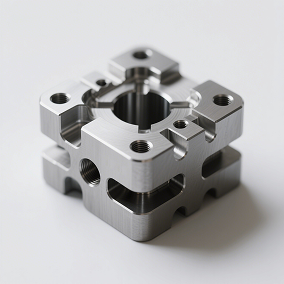

We provide CNC machining for both carbon steel and alloy steel parts with tight tolerances and fast turnaround.

Tolerance down to 0.0005 inches(0.01mm)

No minimum order quantity

Over 40 Certified Materials

Delivery in as little as 5 days

Utilizes rotating cutting tools for high-precision machining of flat surfaces, curves, and complex parts, ideal for mold making, aerospace, and automotive industries.

Uses rotating workpieces and cutting tools for efficient machining of cylindrical components, widely applied in shafts, discs, and precision parts manufacturing.

Enables multi-angle precision cutting, reducing setups and machining complex surfaces, perfect for high-end aerospace, medical devices, and precision mold manufacturing.

| Alloy | Temp Resistance (°C) | Hardness (HB) | Cost | Common Applications | Surface Treatment Limitations | Key Features |

| 1018 | ~480°C | 126–163 | $$ | Shafts, pins, base plates | Requires coating for rust protection | Easy to machine, low cost |

| 1020 | ~480°C | 130–160 | $$ | Automotive parts, tubes | Poor corrosion resistance | Good weldability, moderate strength |

| 1025 | ~500°C | 140–170 | $$ | Machinery parts, fasteners | Needs surface treatment for wear resistance | Balance of strength and machinability |

| 1045 | ~600°C | 180–220 | $$$ | Gears, bolts, shafts | Requires heat treatment for best performance | High strength, heat-treatable |

| 1215 | ~450°C | 130–170 | $$ | High-speed machining parts | Low strength, not suitable for load-bearing | Excellent machinability, ideal for mass production |

| 4130 | ~650°C | 190–240 | $$$ | Aircraft parts, roll cages | Requires skilled heat treatment | High toughness, weldable |

| 4140 | ~650°C | 200–250 | $$$ | Tooling, molds, axles | Needs post-treatment after machining | Strong, wear-resistant, heat-treatable |

| 4340 | ~700°C | 250–300 | $$$$ | Aerospace, high-load parts | Poor machinability when hardened | Excellent fatigue & impact resistance |

| 5140 | ~620°C | 180–230 | $$$ | Transmission shafts, gears | Requires heat treatment | Wear resistance, good toughness |

For a high-gloss and mirror-like finish. Commonly used in decorative or sanitary applications. | Not protective, may show scratches easily. | SUS304, SUS316, SUS303 |

Black Oxide Provides mild corrosion resistance with a matte black appearance. | Not suitable for outdoor/high-humidity environments. | 1018, 1045, 1215 |

Zinc Plating Adds corrosion resistance and a bright/silver finish. | Thin coating, not ideal for wear surfaces. | 1020, 1045, 5140 |

Nickel Plating Enhances corrosion and wear resistance with decorative appearance. | Increases part cost, requires strict pre-treatment. | 1045, 4130, 4340 |

Chrome Plating Adds hardness, wear resistance, and mirror-like finish. | Brittle layer, higher cost, poor on complex shapes. | 1045, 4140, 4340 |

Phosphate Coating Improves paint adhesion and offers mild corrosion protection. | Not decorative; color may vary. | 1025, 1045, 5140 |

Powder Coating Durable, colorful coating for protection and appearance. | Adds thickness, not suitable for tight-tolerance parts. | Most steels, especially 1018, 1045 |

Heat Treatment Enhances hardness, strength, and wear resistance. | Changes internal stress; not a visual finish. | 1045, 4140, 4340, 5140 |

Carburizing / Nitriding Increases surface hardness while keeping the core tough. | Requires special alloy steels and controlled environment. | 20Cr, 4130, 5140 |

REKO provides CNC machining services for carbon steel and alloy steel components, supporting both prototyping and full-scale production. We deliver high-strength, wear-resistant steel parts to global industries such as automotive, construction, oil & gas, heavy machinery, tooling, and industrial equipment — ensuring tight tolerances, and excellent durability.